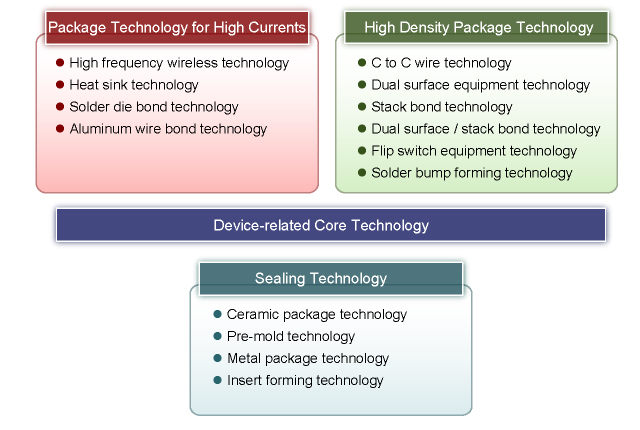

Since we began manufacturing HIC in 1980, we have accumulated rich experience in fields such as the development and manufacturing of high frequency devices / modules, sensor modules, and power modules.

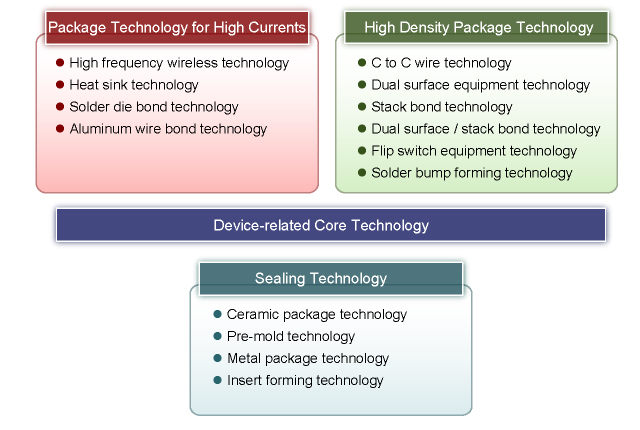

Using the special package technology and highly-reliable package technology we have cultivated through this experience, we contribute to our customers' development.

Business Flow (Contracted Design to Production)

We provide services for the design, prototyping / evaluation, assembly, testing, and reliability tests of various modules to meet our customers' needs.

- - We provide the optimal solution fit to our customer's needs.

- We perform everything from circuit design, module design, and thermal stress design to prototype evaluation.

- - We construct compact, high performance, highly reliable, and low cost packages that can meet the system demands that match each device.

- We perform optimal process design and prototyping to create the package.

- - We select optimal materials based on the package and process design.

- We procure materials in a timely fashion for prototyping to mass production.

- - We have an assembly line that supports various kinds of packages, such as ceramics, organic substrates, pre-molds, injection molds, and CAN.

- We flexibly support production of various kinds in small quantities to mass production.

- - Through contact technology and automating lead cuts, forming, and marking to fit each module, we provide tests that are highly reproducible and efficient for production.

- We follow our customers' needs regarding the pressure, acceleration, and magnetic function of each sensor device, providing high temperature / low temperature trimming and tests.

- - The required quality is established from the design stage based on various reliability tests in product development.

- We provide products with a stable quality through periodic reliability tests during mass production and shipment inspections (QAT).

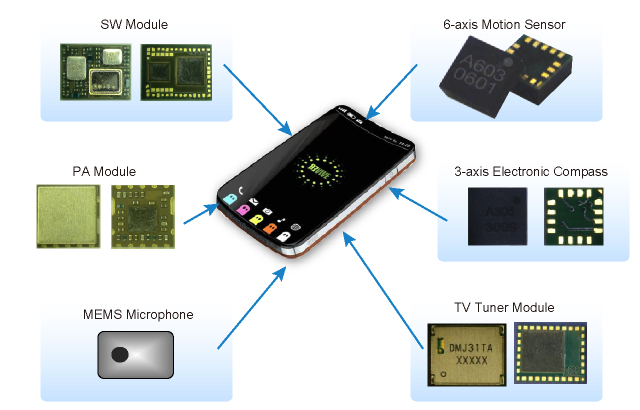

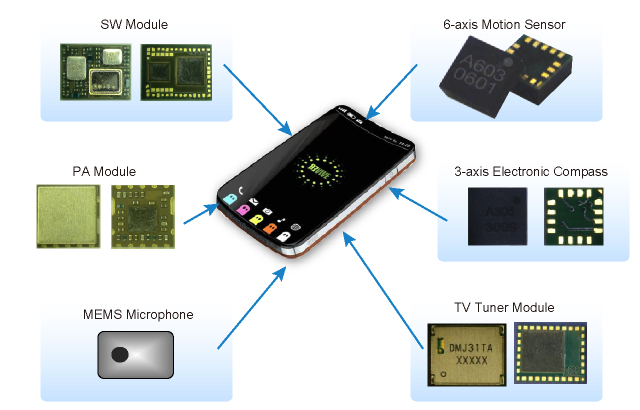

Examples of module products for cellular phones

We provide high frequency and sensor module products for cellular phones that are compact, high performance, and low cost, covering everything from development to production.

- - Low stress, high density 3-dimensional hollow PKG structure, enhanced function, and embeddable high density PKG structure with high frequency / good heat characteristics, provided by LTCC substrates

- …

- [MEMS Sensor Devices, High Frequency Devices]

- - High density PKG structure provided by fine-pitch / multi-layer / cavity organic substrates

- …

- [High Frequency Devices / MEMS Sensor Devices]

Examples of module products for vehicles

We provide highly reliable, high performance sensor and power module products for vehicles, covering everything from development to production.

- - Highly reliable and high performance hollow PKG structure through organic substrates and CAN packages

- …

- [Pressure sensor modules]

- - Highly exoergic, highly reliable PKG structure through our original thick film resistance substrate

- …

- [Power / Pressure sensor modules]

- - Low cost hollow PKG structure with great flexibility through pre-molds

- …

- [MEMS sensor modules]